ball mill is suitable for grinding all kinds of ores and other materials, and is widely used in mineral processing, building materials and chemical industries.

Application fields:

cement, silicate, new construction materials, refractory materials, chemical fertilizer, black and non-ferrous metal dressing, glass and ceramics industries.

Application materials:

fly ash, limestone, quartz, aluminum powder, coal powder, steel slag, ore, potash feldspar, iron ore, iron slag, aluminum slag, silicon carbide, alumina, coal gangue, etc.

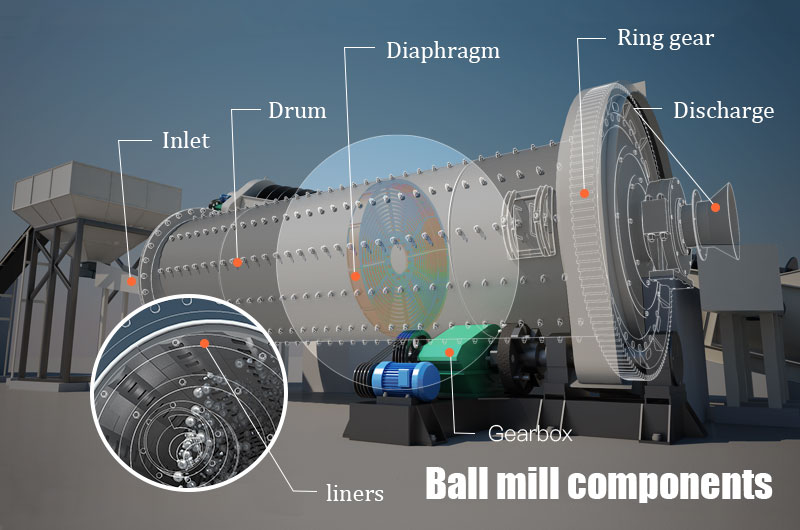

Ball mill is a key equipment for crushing materials after they are broken. This type of grinding mill is a mill that is loaded with a certain number of steel balls as grinding media. Ball mills are suitable for grinding various ores and other materials. They are widely used in mineral processing, building materials and chemical industries. They can be divided into two types of grinding methods: dry type and wet type. According to different discharge methods, they can be divided into two types: grid type and overflow type.

The material enters the first chamber of the mill uniformly through the feeding device through the feeding hollow shaft screw. There is a stepped lining plate or a corrugated lining plate inside the chamber, which is filled with steel balls of different specifications. The rotation of the cylinder generates centrifugal force to bring the steel balls to a certain height and then drop them, producing a heavy impact and grinding effect on the material. After the material reaches rough grinding in the first warehouse, it enters the second warehouse through a single-layer partition board, which is embedded with a flat lining board and steel balls inside. The material is further ground. The powdered material is discharged through the discharge grate to complete the grinding operation.

| Model | Cylinder Speed (r/min) | Balls Load (t) | Feeding Size (mm) | Discharge Size (mm) | Capacity (t/h) | Motor Power (kw) | Weight (t) |

| Φ900×1800 | 36 | 1.5 | ≤20 | 0.075-0.89 | 0.65-2 | 18.5 | 4.6 |

| Φ900×3000 | 36 | 2.7 | ≤20 | 0.075-0.89 | 1.1-3.5 | 22 | 5.6 |

| Φ1200×2400 | 36 | 3 | ≤25 | 0.075-0.6 | 2.2-4.8 | 30 | 10.5 |

| Φ1200×3000 | 36 | 3.5 | ≤25 | 0.074-0.4 | 2.7-5 | 37 | 11.8 |

| Φ1200×4500 | 32.4 | 5 | ≤25 | 0.074-0.4 | 4-7.5 | 55 | 13.8 |

| Φ1500×3000 | 29.7 | 7.5 | ≤25 | 0.074-0.4 | 4.3-8 | 75 | 15 |

| Φ1500×3500 | 29.7 | 7.5 | ≤25 | 0.074-0.4 | 4.5-9 | 75 | 16.5 |

| Φ1500×4500 | 27 | 11 | ≤25 | 0.074-0.4 | 6-12 | 90 | 18 |

| Φ1500×5700 | 28 | 12 | ≤25 | 0.074-0.4 | 7-15 | 130 | 22 |

| Φ1830×3000 | 25.4 | 11 | ≤25 | 0.074-0.4 | 6.5-12 | 130 | 28 |

| Φ1830×3600 | 25.4 | 13 | ≤25 | 0.074-0.4 | 8-13 | 130 | 30 |

| Φ1830×4500 | 25.4 | 15 | ≤25 | 0.074-0.4 | 10-18 | 155 | 32 |

| Φ1830×6500 | 24.1 | 21 | ≤25 | 0.074-0.4 | 14-26 | 210 | 35 |

| Φ1830×7000 | 25 | 23 | ≤25 | 0.074-0.4 | 15-28 | 245 | 39 |

| Φ2100×3000 | 23.7 | 15 | ≤25 | 0.074-0.4 | 9-16 | 180 | 37 |

| Φ2100×3600 | 23.7 | 18 | ≤25 | 0.074-0.4 | 10-19 | 210 | 39 |

| Φ2100×4500 | 23.7 | 24 | ≤25 | 0.074-0.4 | 13-24 | 245 | 41 |

| Φ2100×7000 | 23.7 | 26 | ≤25 | 0.074-0.4 | 20-37 | 280 | 55 |

| Φ2200×4500 | 21.5 | 27 | ≤25 | 0.074-0.4 | 14-26 | 280 | 50 |

| Φ2200×7000 | 21.7 | 35 | ≤25 | 0.074-0.4 | 22-41 | 380 | 60 |

| Φ2400×3600 | 21 | 23 | ≤25 | 0.074-0.4 | 14-25 | 320 | 63 |

| Φ2400×4500 | 21 | 27 | ≤25 | 0.074-0.4 | 17-32 | 380 | 69 |

| Φ2400×7000 | 20.9 | 42 | ≤25 | 0.074-0.4 | 26-49 | 480 | 80 |

| Φ2700×3600 | 20.7 | 33 | ≤25 | 0.074-0.4 | 19-32 | 380 | 90 |

| Φ2700×4000 | 20.7 | 35 | ≤25 | 0.074-0.4 | 20-36 | 380 | 94 |

| Φ2700×4500 | 20.7 | 38 | ≤25 | 0.074-0.4 | 21-40 | 480 | 98 |

| Φ2700×7000 | 20.7 | 55 | ≤25 | 0.074-0.4 | 33-62 | 630 | 116 |

| Φ3200×4500 | 19 | 56 | ≤25 | 0.074-0.4 | 35-68 | 800 | 132 |

| Φ3200×7000 | 18 | 73 | ≤25 | 0.074-0.4 | 47-78 | 1250 | 185 |

| Φ3600×4500 | 17 | 76 | ≤25 | 0.074-0.4 | 49-82 | 1250 | 185 |

| Φ3600×6000 | 17 | 100 | ≤25 | 0.074-0.4 | 52-96 | 1400 | 235 |

| Φ3600×8500 | 17 | 130 | ≤25 | 0.074-0.4 | 70-130 | 1800 | 270 |

| Φ3800×6500 | 16.7 | 121 | ≤25 | 0.074-0.4 | 73-137 | 1800 | 277 |

| Φ3800×8500 | 16.7 | 158 | ≤25 | 0.074-0.4 | 82-143 | 2000 | 305 |

| Φ4000×6000 | 16.7 | 135 | ≤25 | 0.074-0.4 | 90-160 | 2000 | 315 |

We are a professional machinery manufacturer that produces and sells our own products.

You can bring materials to the factory to test the machine

We will customize the solution according to your needs

60S Quick response

Minutes Technical reply

Hours design proposal

whatsApp

whatsApp