The ball press is mainly used to press the powdery materials which are difficult to be shaped, and it is the ball making equipment which presses all kinds of powder materials into higher capacity.

Application fields:

Widely used in coal, mining, metallurgy, refractory materials, building materials and other industries.

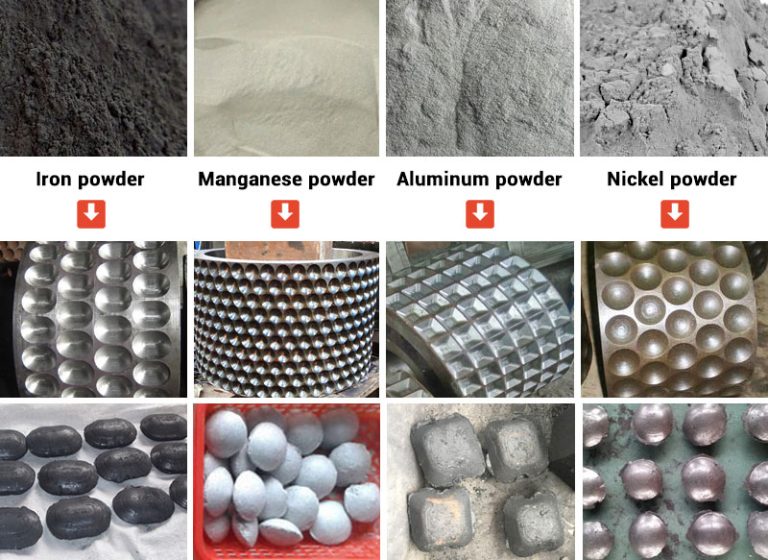

Applicable materials:

Coal powder, iron powder, coking coal, aluminium powder, iron filings, iron oxide, carbon powder, charcoal powder, slag, gypsum, tailings, sludge, kaolin, activated carbon, coke, etc. Various kinds of powders, dusts, wastes, slags, etc.

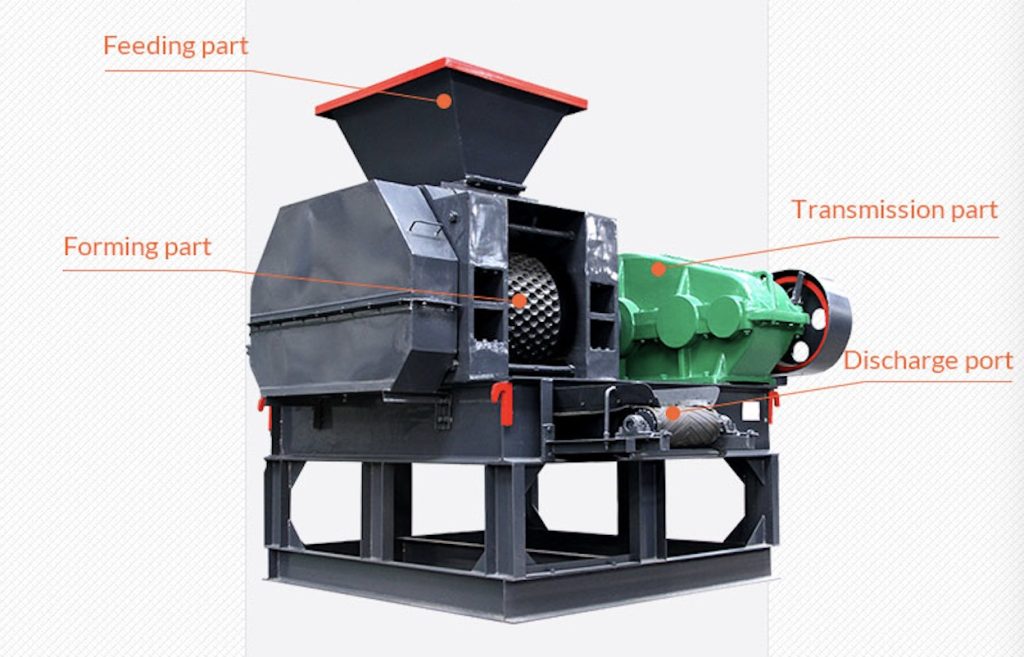

Briquette Machine is also called mineral powder ball press machine, pair of stick ball press machine, lime powder ball press machine, etc. This briquette machine presses various powders into high-capacity balls, primarily consisting of a press shaft assembly, frame, reducer, motor, and belt conveyor. The ball pressing machine molds the material into energy-saving and environmentally friendly balls that are easy to transport. This process significantly improves the utilization rate of waste materials. With excellent economic and social benefits, the molded balls are widely used in refractory, power plants, metallurgy, chemical industry, energy, transportation, and heating sectors. To meet combustion and smelting requirements, manufacturers typically shape the agglomerate into 20-80mm sizes, forming round, oval, square, pillow, or bread shapes, or customize them according to customer specifications.

The quantitative device evenly delivers the material into the feed hopper of the ball making machine. The adjusting gate then uniformly distributes the material into the crushing roller. The twin rolls apply high pressure to compress the raw material, while the pre-pressure screw feeds it into the roll gap. This intense mechanical force molds the material into dense balls, which then smoothly detach from the rotating rolls upon completion.

| Model | ZY-290 | ZY-360 | ZY-430 | ZY-500 | ZY-650 | ZY-750 | ZY-850 |

| Capacity | 1-2t/h | 3-4t/h | 6-8t/h | 8-11t/h | 11-15t/h | 20-25t/h | 25-28t/h |

| Roller width | 200mm | 250mm | 280mm | 300mm | 336mm | 400mm | 500mm |

| Diameter of roller sheer | 290mm | 360mm | 430mm | 500mm | 650mm | 750mm | 850mm |

| Motor power | 5.5kw | 7.5kw | 15kw | 18.5kw | 22kw | 45kw | 55kw |

| Size | 1.5*1.25*1.55m | 1.6*1.45*1.65m | 2.6*1.7*2.1m | 2.6*2*2.1m | 2.6*3.3*2.3 | 3.85*2.2*2.3m | 3.85*2.6*2.5m |

| Weight | 550kg | 750kg | 880kg | 1050kg | 1600kg | 2500kg | 3800kg |

We are a professional machinery manufacturer that produces and sells our own products.

You can bring materials to the factory to test the machine

We will customize the solution according to your needs

60S Quick response

Minutes Technical reply

Hours design proposal

whatsApp

whatsApp