Hydraulic Cone Crusher is an advanced model optimised on the basis of Spring Cone Crusher with large output and high crushing efficiency.

Application fields:

Metallurgical, building materials, road construction, chemical, silicate, etc.

Application materials:

suitable for medium and fine crushing of basalt, river pebbles, granite, quartzite, metal ores and other high hardness materials.

Hydraulic Cone Crusher is an international advanced cone crusher, which has functions that other crushers do not have. The Hydraulic Cone Crusher has good granularity of finished products according to the principle of laminar crushing, and the hydraulic lubrication control system enables the bearings of this machine to be effectively protected. It is suitable for crushing all kinds of materials above medium hardness. Our company has improved the production capacity and crushing efficiency by designing and developing the use of high-performance crushing cavity shape and high crushing frequency combination, also expanding the scope of application, such as iron ore, non-ferrous metals, granite, limestone, quartz, sandstone, river pebbles and other ores and rocks.

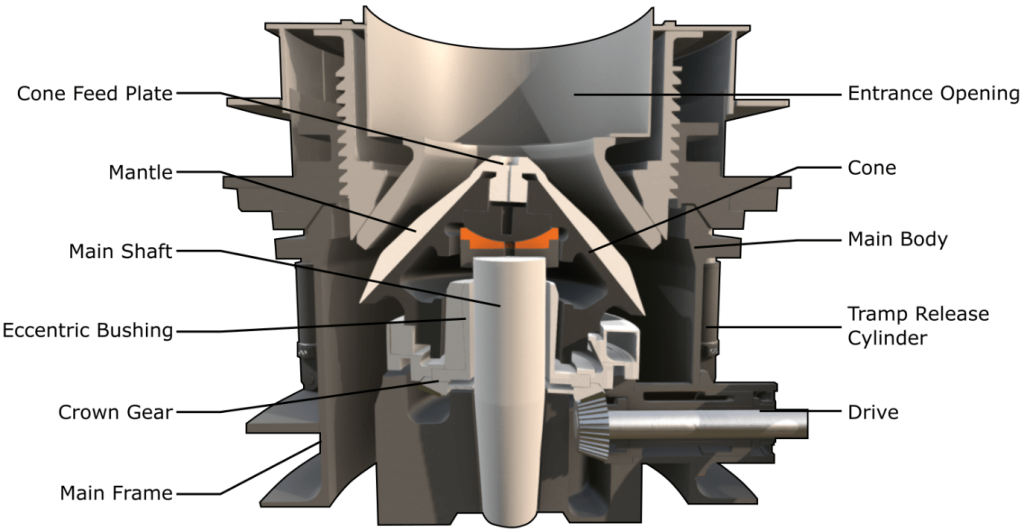

The structure of hydraulic cone crusher mainly consists of frame, fixed cone, moving cone assembly, spring mechanism, shaft frame and transmission device. Through the motor drive to make the linkage of gears, the transmission shaft and transmission gears drive the eccentric sleeve to rotate. The dynamic cone of the hydraulic cone crusher makes rotating movement under the action of eccentric sleeve, the dynamic cone and the fixed cone are close to each other or separated to impact and crush the materials, and finally form stable aggregate, the qualified raw materials fall from the gap of the crushing wall, and the rest continue to be crushed until the required particle size is reached.

| Model | Cavity | Standard type | Shorthead type | Capacity(t/h) | Motor Power(kw) | ||

| Feeder openingsize(mm) | Outlet settingsize(mm) | Feeder openingsize(mm) | Outlet settingsize(mm) | ||||

| HP200 | Coarse | 180 | 19 | 76 | 10 | 145-250 | 130-200 |

| Medium | 120 | 17 | 54 | 6 | 135-235 | ||

| Fine | 90 | 13 | 23 | 6 | 115-220 | ||

| UltrafineFine | 70 | 10 | 10 | 5 | 90-190 | ||

| HP300 | Coarse | 210 | 20 | 75 | 10 | 190-380 | 180-250 |

| Medium | 150 | 15 | 50 | 8 | 175-320 | ||

| Fine | 110 | 10 | 20 | 6 | 145-280 | ||

| UltrafineFine | 80 | 10 | 20 | 6 | 110-240 | ||

| HP400 | Coarse | 240 | 25 | 90 | 10 | 285-560 | 280-355 |

| Medium | 195 | 20 | 50 | 8 | 250-490 | ||

| Fine | 110 | 14 | 40 | 6 | 180-345 | ||

| UltrafineFine | 90 | 10 | 30 | 6 | 135-320 | ||

| HP500 | Coarse | 285 | 25 | 90 | 13 | 400-790 | 355-450 |

| Medium | 200 | 20 | 55 | 10 | 335-610 | ||

| Fine | 130 | 16 | 40 | 8 | 280-460 | ||

| UltrafineFine | 95 | 13 | 35 | 6 | 180-435 | ||

We are a professional machinery manufacturer that produces and sells our own products.

You can bring materials to the factory to test the machine

We will customize the solution according to your needs

60S Quick response

Minutes Technical reply

Hours design proposal

whatsApp

whatsApp