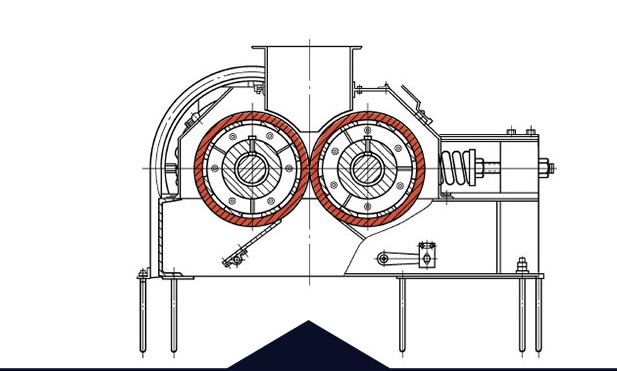

Roller crusher is a kind of crushing machine that uses two relatively rotating rollers to crush materials. It mainly consists of roller group, roller support bearing, clamping adjustment device and driving device.

Application fields:

metallurgy, building materials, refractory materials and river pebbles.

Applicable materials:

secondary and fine crushing materials with soft or middle like coal,coke,limestone,clinker mineral,slag,shale and so on.

Double roller crusher is mainly used for crushing ore. It has the advantages of small size, large crushing ratio (5-8), low noise, simple structure and convenient maintenance. Double roller crusher is suitable for fine crushing process with feed particle size less than 80mm and finished particle size of 50μm-20mm.

The tooth roller crusher has large crushing capacity, optimized tooth shape design, high efficiency and low consumption, and uniform particle output. This product has the advantages of high efficiency, energy saving and environmental protection. It has become the preferred equipment for thermal power plants to replace imported crushing equipment.

The material enters between the two rollers through the feed port and is subjected to the squeezing and shearing force of the rollers, thereby achieving a crushing effect. The adjustment device can change the gap between the rollers to control the material output particle size. When encountering hard or unbreakable materials, the rollers can automatically retreat by the action of hydraulic cylinders or springs to increase the gap between the rollers, thereby protecting the machine from damage.

The double-roll crusher allows for high flexibility and customizability, enabling customization and modification to meet different customer needs and adapt to various production environments and material characteristics.

| Model | Roller Diameter (mm) | Roller Length (mm) | Feeding Size (mm) | Capacity (t/h) | Motor Power (kw) |

| 2PG-400X250 | 400 | 250 | ≤ 25 | 2-10 | 2*5.5 |

| 2PG-610X400 | 610 | 400 | ≤ 30 | 5-20 | 2*15 |

| 2PG-610X750 | 610 | 750 | ≤ 30 | 5-25 | 2*18.5 |

| 2PG-750X400 | 750 | 400 | ≤ 30 | 10-40 | 2*18.5 |

| 2PG-800X600 | 800 | 600 | ≤ 40 | 12-50 | 2*22 |

| 2PG-800X800 | 800 | 800 | ≤ 40 | 20-60 | 2*22 |

| 2PG-900X900 | 900 | 900 | ≤ 50 | 50-100 | 2*37 |

| 2PG-1200X900 | 1200 | 900 | ≤ 50 | 60-130 | 2*45 |

| 2PG-1200X1200 | 1200 | 1200 | ≤ 50 | 80-150 | 2*45 |

We are a professional machinery manufacturer that produces and sells our own products.

You can bring materials to the factory to test the machine

We will customize the solution according to your needs

60S Quick response

Minutes Technical reply

Hours design proposal

whatsApp

whatsApp