Dust collectors are industrial suction equipment used for industrial purposes to suck up particles, dust and fumes, oil and water from waste media in production.

Application fields:

building materials, cement, metallurgy, machinery, chemicals, refractory materials and other industries.

Applicable materials:

Drying limestone, sand, coal, slag, clay, wood chips, sawdust, mineral powder, etc.

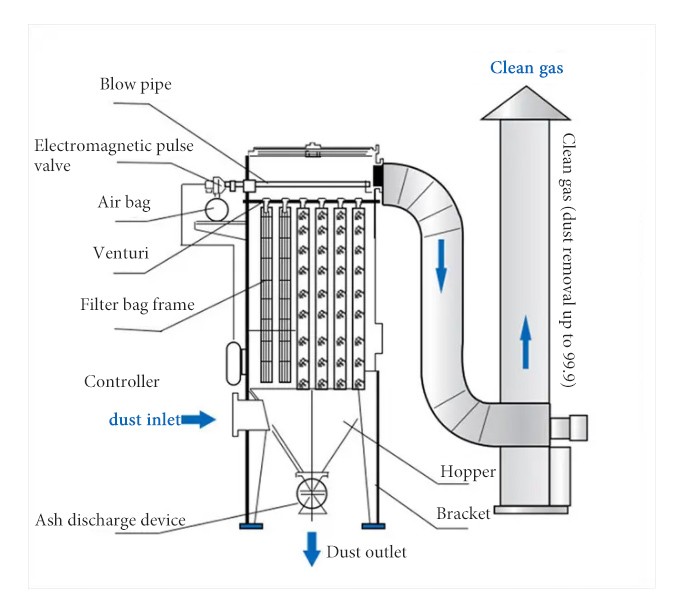

Dust collector is devices that use compressed air to remove dispersed fine particles or dust. In order to correctly design and select dust removal equipment in engineering design, it is necessary to understand the main physical and chemical properties of dust to achieve better dust removal effects.

The vacuum cleaner is mainly powered by a vortex air pump or fan for exhaust. After the debris enters the machine through the suction nozzle and the dust suction tube, it first enters a filter bag and undergoes primary filtration. The air carrying fine dust then passes through a special filter and undergoes secondary filtration before being discharged through the fan exhaust port.

| Model | Processing Air Quantity (m³/h) | Total Filtration Area (m²) |

| ppcs32-3 | 6900 | 93 |

| ppcs32-4 | 8930 | 124 |

| ppcs32-5 | 11160 | 155 |

| ppcs32-6 | 13390 | 186 |

| ppcs64-4 | 17300 | 248 |

| ppcs64-5 | 22300 | 310 |

| ppcs64-6 | 26700 | 372 |

| ppcs64-7 | 31200 | 434 |

| ppcs64-8 | 35700 | 496 |

We are a professional machinery manufacturer that produces and sells our own products.

You can bring materials to the factory to test the machine

We will customize the solution according to your needs

60S Quick response

Minutes Technical reply

Hours design proposal

whatsApp

whatsApp