The hammer crusher can break materials of different sizes into uniform particles to facilitate processing in the next process.

Application areas:

cement, chemical, electric power, metallurgy and other industries

Application materials:

Limestone, coal, salt, gypsum, alum, bricks

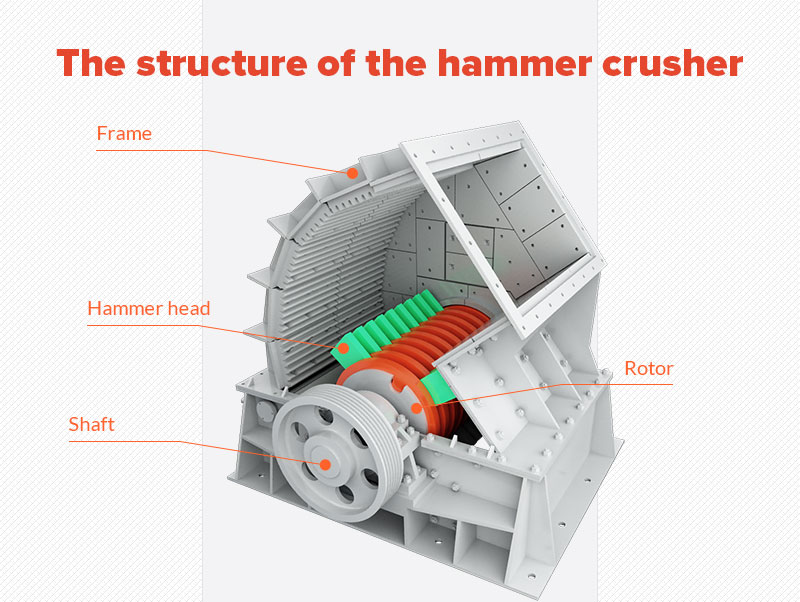

The hammer crusher mainly relies on impact energy to complete the material crushing operation. When the hammer crusher is working, the motor drives the rotor to rotate at high speed, and the material enters the crusher cavity evenly. The high-speed rotating hammer head impacts, shears and tears the material, causing the material to be broken. At the same time, the gravity of the material itself makes the material from The high-speed rotating hammer head rushes towards the baffle and screen bars in the frame body. The screen plate retains materials larger than the screen hole size.The hammer continues hitting and grinding these materials until they break down to the required discharge granularity.Finally, the properly sized materials pass through the screen holes and discharge from the machine.

The motor drives the rotor to rotate at high speed, propelling materials evenly into the crusher cavity.Inside the cavity, the high-speed rotating hammers actively impact, shear, and tear the materials.At the same time, the gravity of the materials themselves causes the materials to rush from the high-speed rotating hammers to the baffle in the frame. Materials larger than the size of the sieve holes are retained on the sieve plate and continue to be hit and ground by the hammers until they are crushed to the required particle size and finally discharged from the machine through the sieve plate.

| Specifications and models | Rotating speed | Feed particle size | Discharge particle size | Yield | weight | Power | Dimensions |

| PC-400×300 | 1450 | ≤100 | 10 | 3-10 | 0.8 | 11 | 855×795×860 |

| PC-500×350 | 1250 | ≤100 | 15 | 5-15 | 1.2 | 18.5 | 1200×1114×1114 |

| PC-600×400 | 1000 | ≤220 | 15 | 5-25 | 1.5 | 22 | 1055×1022×1122 |

| PC-800×600 | 980 | ≤350 | 15 | 10-50 | 3.1 | 55 | 1360×1330×1020 |

| PC-800×800 | 980 | ≤350 | 15 | 10-60 | 3.5 | 75 | 1440×1740×1101 |

| PC-1000×800 | 1000 | ≤400 | 13 | 20-75 | 7.9 | 115 | 3514×2230×1515 |

We are a professional machinery manufacturer that produces and sells our own products.

You can bring materials to the factory to test the machine

We will customize the solution according to your needs

60S Quick response

Minutes Technical reply

Hours design proposal

whatsApp

whatsApp