The heavy hammer crusher adopts advanced production technology to achieve one-time feeding and forming

Application fields:

mine, metallurgy, building material, highway, railway, water conservancy and chemical industry

Applicable materials:

limestone, coal, salt, gypsum, alum, brick, tile, coal gangue, etc.

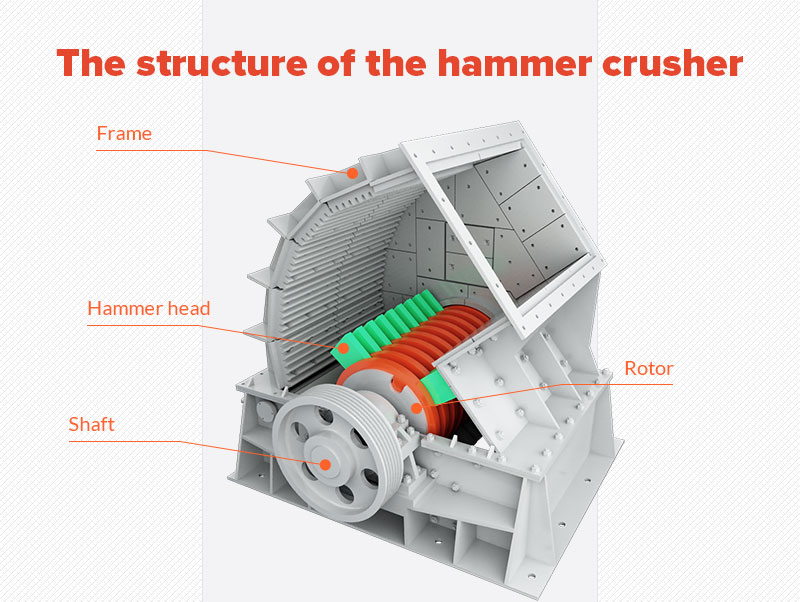

The heavy hammer crusher is a type of crushing equipment, and is also a relatively advanced type of equipment in the hammer crusher series in the industry. It adopts advanced production technology to achieve one-time feeding and forming, and has the characteristics of high efficiency, energy saving and environmental protection. The finished material can be adjusted according to demand, with coarse, medium and fine, and various specifications; no flakes, no smooth bodies, and multi-angles and edges to ensure positive compressive strength. This crusher replaces the initial crushing process of the jaw crusher and becomes a new type of machine that completes the crushing of large and small materials at one time. It has large output, high efficiency, low power, saves manpower and material resources, and reduces the cost of material crushing.

The material is fed into the machine from the upper feeding port and crushed by the impact, shearing and grinding of the high-speed hammer. A sieve plate is provided at the bottom of the rotor. The material smaller than the sieve hole size in the crushed material is discharged through the sieve plate, and the coarse particles larger than the sieve hole size are retained on the sieve plate and continue to be hit and ground by the hammer, and then discharged out of the machine through the sieve plate.

| Model | Feeding Size (W*L)(mm) | Rotor Size (Dia.xL)(mm) | Input Size(mm) | Power(KW) | Capacity(t/h) | Overall Dimension (mm) |

| PCZ-0808 | 800*5000 | 850*790 | ≤450 | 55-75 | 50-90 | 1760*1700*1540 |

| PCZ-1308 | 850*800 | 1310*790 | ≤600 | 55*2 | 100-160 | 2818*2100*2390 |

| PCZ-1510 | 1000*850 | 1500*950 | ≤750 | 132*2 | 160-210 | 3260*2370*2750 |

| PCZ-1512 | 1210*900 | 1500*1160 | ≤750 | 160*2 | 220-350 | 3260*2580*2750 |

| PCZ-1615 | 1500X1200 | 1650*1452 | ≤1000 | 200*2 | 350-500 | 3456*2915*3185 |

| PCZ-2015 | 1500X1400 | 2000*1500 | ≤1200 | 315*2 | 500-800 | 3880*2990*3560 |

We are a professional machinery manufacturer that produces and sells our own products.

You can bring materials to the factory to test the machine

We will customize the solution according to your needs

60S Quick response

Minutes Technical reply

Hours design proposal

whatsApp

whatsApp