High pressure briquette machine, also called dry powder ball press, presses powder into balls for smelting use

Application fields:

Widely used in coal, mining, metallurgy, refractory materials, building materials and other industries.

Applicable materials:

Coal powder, iron powder, coking coal, aluminium powder, iron filings, iron oxide, carbon powder, charcoal powder, slag, gypsum, tailings, sludge, kaolin, activated carbon, coke, etc. Various kinds of powders, dusts, wastes, slags, etc.

The series of high pressure briquette machine and ordinary ball press different point material is mainly dry powder, through the forced pressurisation, pre-pressure spiral precision processing, made of higher density ball blanks. Pressing and moulding process without adding water and additives stirring, is widely used in metallurgy, chemical, coal and refractory materials and other industries, the main design of capacity is to press dry powder into ball shape, easy to transport, improve the utilization rate of waste.

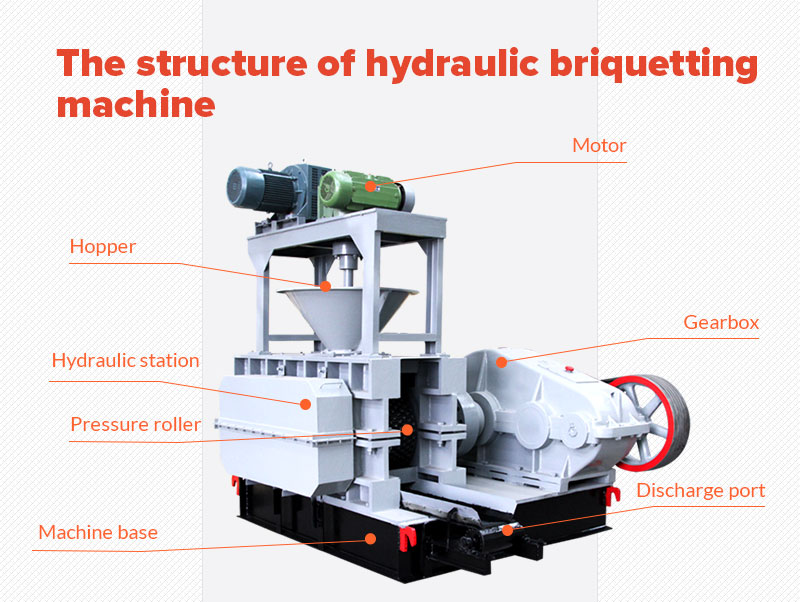

Material from the storage bin through the quantitative equipment uniformly into the moulding machine hopper, through the hopper on the adjusting gate adjustment, so that the material uniformly into the middle of the rollers, isotropic reverse operation of the rollers for compression of the material unit of the moulding pressure from a small change in the centre line of the rollers at the moulding pressure to reach the maximum value, the material over the line, the moulding pressure quickly become smaller to enable the material into the state of the de-balling, and the smooth de-balling.

| Model | Roll diameter (mm) | Roll width (mm) | Total pressure(t) | Maximum line pressure (t/cm) | Main motor power(KW) | Outpu (t/h) | weight(t) |

| GY520-150 | 520 | 196 | 150 | 8 | 55 | 2.2-3.5 | 13 |

| GY650-220 | 650 | 205 | 220 | 11 | 90 | 4-6.5 | 19.2 |

| GY750-300 | 750 | 280 | 300 | 11 | 185 | 6-8.5 | 34 |

| GY1000-350 | 1000 | 460 | 350 | 8 | 250 | 10-15 | 50.8 |

| GY1000-450 | 1000 | 500 | 450 | 9 | 280 | 14-17 | 58.5 |

| GY1000-500 | 1000 | 500 | 500 | 10 | 315 | 15-20 | 58.5 |

We are a professional machinery manufacturer that produces and sells our own products.

You can bring materials to the factory to test the machine

We will customize the solution according to your needs

60S Quick response

Minutes Technical reply

Hours design proposal

whatsApp

whatsApp