Rod mill is a mill with steel rods as grinding media in the cylinder.

Application fields:

metallurgy, chemical industry, glass and other industries, can also be used for building sand.

Application materials:

Crushing feldspar, quartz, pebbles and other ore materials

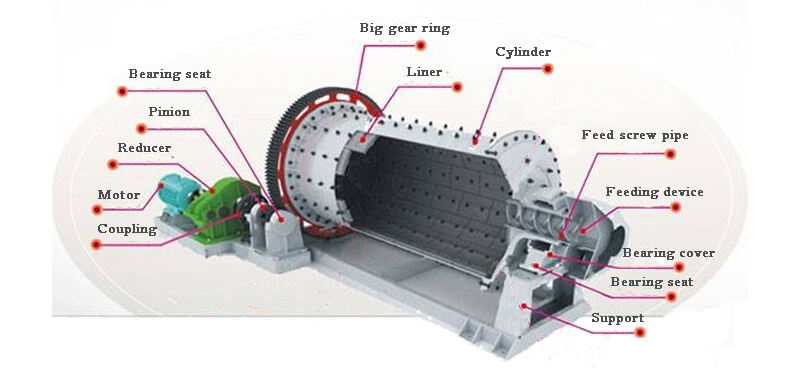

Rod Mill is mainly composed of motor, main reducer, transmission part, cylinder part, main bearing, slow transmission part, feed part, discharge part, annular seal, thin oil lubrication station, large and small gear injection lubrication, foundation part, etc. The main reducer is parallel shaft and hardened tooth surface. The cylinder is equipped with appropriate grinding medium - steel rod. Under the action of centrifugal force and friction, the grinding medium continuously enters the cylinder from the feeding part, is crushed by the moving grinding medium, and the product is discharged out of the machine through overflow and continuous feeding force for the next process.

Rod mill is an asynchronous motor connected to a small gear through a reducer, which directly drives the surrounding large gear to reduce speed and rotate, driving the rotating part to rotate. The cylinder is equipped with appropriate grinding media - steel rods. Under the action of centrifugal force and friction, the material to be ground continuously enters the cylinder from the feeding part, is crushed by the moving grinding media, and is discharged out of the machine through overflow and continuous feeding force for the next process.

| Model | Cylinder Specifications (mm) | Cylinder Speed (r/min) | Rod Quantity (t) | Feed Particle Size (mm) | Discharge Particle Size (mm) | Capacity (t/h) | Motor Power (kw) | Weight (t) | |

| Diameter | Length | ||||||||

| MB0918 | 900 | 1800 | 29-31.3 | 2.3 | ≤25 | 0.16-5 | 1.6-6 | 22 | 4.8 |

| MB0924 | 900 | 2400 | 29-35.4 | 3.1 | ≤25 | 0.16-5 | 2.9-10 | 30 | 5.3 |

| MB1224 | 1200 | 2400 | 27-34 | 6.5 | ≤25 | 0.16-5 | 5.0-13 | 37 | 11.8 |

| MB1530 | 1500 | 3000 | 26.5-29.5 | 11.5 | ≤25 | 0.16-5 | 6.0-25 | 75 | 17.2 |

| MB1545 | 1500 | 4500 | 26.5-29.5 | 14 | ≤25 | 0.16-5 | 10-35 | 90 | 22 |

| MB1830 | 1800 | 3000 | 21.6-22.8 | 17.5 | ≤25 | 0.16-5 | 12-40 | 155 | 29.5 |

| MB1855 | 1800 | 5500 | 21.6-22.8 | 23 | ≤25 | 0.16-5 | 12-60 | 185 | 33 |

| MB2130 | 2100 | 3000 | 19-21 | 23.2 | ≤25 | 0.16-5 | 20-80 | 210 | 37 |

| MB2155 | 2100 | 5500 | 19-21 | 26 | ≤25 | 0.16-5 | 25-100 | 280 | 45 |

| MB2430 | 2400 | 3000 | 18-20 | 32 | ≤25 | 0.16-5 | 30-130 | 280 | 60 |

| MB2455 | 2400 | 5500 | 18-20 | 46 | ≤25 | 0.16-5 | 50-180 | 380 | 79 |

| MB2755 | 2700 | 5500 | 17.2-18.5 | 51 | ≤25 | 0.16-5 | 80-250 | 560 | 112 |

| MB3055 | 3000 | 5500 | 17-18 | 62 | ≤25 | 0.16-5 | 120-300 | 630 | 123 |

| MB3255 | 3200 | 5500 | 16.5-18 | 70 | ≤25 | 0.16-5 | 150-380 | 800 | 138 |

| MB3660 | 3600 | 6000 | 16-18 | 93 | ≤25 | 0.16-5 | 200-580 | 1600 | 210 |

We are a professional machinery manufacturer that produces and sells our own products.

You can bring materials to the factory to test the machine

We will customize the solution according to your needs

60S Quick response

Minutes Technical reply

Hours design proposal

whatsApp

whatsApp