Rotary dryer is a kind of directly heated continuous rotating cylinder drying equipment, its working principle is to use thermal energy to heat and evaporate the moisture in the material, so that the material is dried.

Application fields:

Metallurgy, building materials, light industry, chemical industry

Applicable materials:

Drying limestone, sand, coal, slag, clay, wood chips, sawdust, mineral powder, etc.

Rotary dryer is mainly used for drying all kinds of mineral raw materials, is a special equipment for drying and dewatering of high humidity materials. It is mainly composed of rotary, lifting plate, transmission device, support device sealing ring and other components. The rotary dryer is mainly used for drying limestone, coal powder, slag, clay stone and other materials in building materials, metallurgy, chemical industry and cement plant. The dryer is especially suitable for drying large granular materials in metallurgy, chemical industry, minerals and other industries, and can also dry special powder and granular materials, such as light magnetic powder, graphite, limestone, sand, coal, slag, clay, wood chips, mineral powder and so on.

Rotary dryer is divided into straight drum dryer, double drum dryer and three drum dryer, according to the customer's material, heat source and the degree of drying to choose the right product.

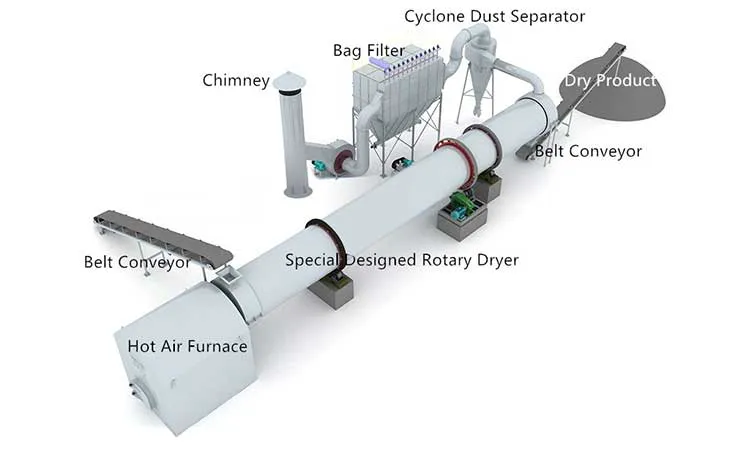

The rotary dryer consists of a horizontal inclined rotating cylinder and power device, dust removal equipment, the use of electricity, diesel engines, wind, combustibles, etc. to generate power, so that the temperature of the material continues to rise, the moisture is evaporated, and ultimately meet the requirements of the moisture of the material from the lower outlet discharge.

| Model | Cylinder Diameter (mm) | Cylinder Length (mm) | Cylinder Volume (m³) | Cylinder Rotary Speed (r/min) | Inclination (%) | Inlet Air Temperature (℃) | Capacity (t/h) | Power (kw) | Weight (t) |

| Φ1×10 | 1000 | 10000 | 7.9 | 1-8 | 3-5 | ≤700 | 1-3.5 | 5.5 | 6.8 |

| Φ1.2×10 | 1200 | 10000 | 11 | 1-6 | 3-5 | ≤700 | 1.8-5 | 7.5 | 10.7 |

| Φ1.2×11.8 | 1200 | 11800 | 13 | 1-6 | 3-5 | ≤700 | 2-6 | 7.5 | 12.3 |

| Φ1.5×11.8 | 1500 | 11800 | 21 | 1-5 | 3-5 | ≤800 | 3.5-8 | 15 | 17.5 |

| Φ1.5×15 | 1500 | 15000 | 26.5 | 1-5 | 3-5 | ≤800 | 4-9 | 15 | 19.2 |

| Φ1.8×11.8 | 1800 | 11800 | 30 | 1-5 | 3-5 | ≤800 | 5-12 | 18.5 | 20.7 |

| Φ1.8×18 | 1800 | 18000 | 45.8 | 1-5 | 3-5 | ≤800 | 5-13 | 22 | 31.2 |

| Φ2×11.8 | 2000 | 11800 | 37 | 1-4 | 3-5 | ≤800 | 7-15 | 18.5 | 28.2 |

| Φ2×20 | 2000 | 20000 | 62.8 | 1-4 | 3-5 | ≤800 | 7-16 | 22 | 44.9 |

| Φ2.2×11.8 | 2200 | 11800 | 44.8 | 1-4 | 3-5 | ≤800 | 9-18 | 22 | 30.5 |

| Φ2.2×18 | 2200 | 18000 | 68 | 1-4 | 3-5 | ≤800 | 10-18 | 30 | 43.3 |

| Φ2.2×20 | 2200 | 20000 | 76 | 1-4 | 3-5 | ≤800 | 12-20 | 30 | 48.8 |

| Φ2.4×20 | 2400 | 20000 | 91 | 1-4 | 3-5 | ≤800 | 15-25 | 37 | 60.5 |

| Φ2.4×23.6 | 2400 | 23600 | 109 | 1-4 | 3-5 | ≤800 | 16-26 | 45 | 69.8 |

| Φ2.8×20 | 2800 | 20000 | 123 | 1-3 | 3-5 | ≤800 | 18-28 | 55 | 65 |

| Φ2.8×28 | 2800 | 28000 | 172 | 1-3 | 3-5 | ≤800 | 20-30 | 75 | 75 |

| Φ3×28 | 3000 | 28000 | 198 | 1-3 | 3-5 | ≤800 | 22-32 | 90 | 91 |

| Φ3.2×32 | 3200 | 32000 | 257 | 1-3 | 3-5 | ≤800 | 24-35 | 110 | 129 |

| Φ3.6×36 | 3600 | 36000 | 366 | 1-3 | 3-5 | ≤800 | 30-43 | 132 | 185 |

We are a professional machinery manufacturer that produces and sells our own products.

You can bring materials to the factory to test the machine

We will customize the solution according to your needs

60S Quick response

Minutes Technical reply

Hours design proposal

whatsApp

whatsApp