Rotary kiln refers to rotary calcining kiln, which belongs to the category of building materials equipment. It can be divided into cement kiln, metallurgical chemical kiln and lime kiln according to the different materials handled.

Application fields:

Cement clinker calcination, metallurgical industry roasting, refractory roasting, chemical plant roasting

Applicable materials:

Cement, Lime, Depleted Iron Ore, Chromite, Nickel Iron Ore, High Bauxite, Chromite, Chromite Powder, etc.

Rotary kiln is a kind of high-temperature processing equipment, through continuous calcination to heat the material to high temperature. Rotary kiln can be divided into cement kiln, metallurgical chemical kiln, lime kiln according to different materials treated. Cement kiln is mainly used for calcining cement clinker, which is divided into two categories: dry cement kiln and wet cement kiln. Metallurgical chemical kilns are mainly used in the metallurgical industry for magnetization roasting of poor iron ore in iron and steel plants; oxidation roasting of chromium and nickel iron ores; roasting of high alumina-vanadium ores in refractory plants and roasting of clinker and alumina hydroxide in aluminium plants; roasting of chrome ores and chrome ore powders and other similar minerals in chemical plants. Lime kiln (i.e. active lime kiln) is used for roasting active lime for iron and steel plants, ferroalloy plants, calcined dolomite and so on.

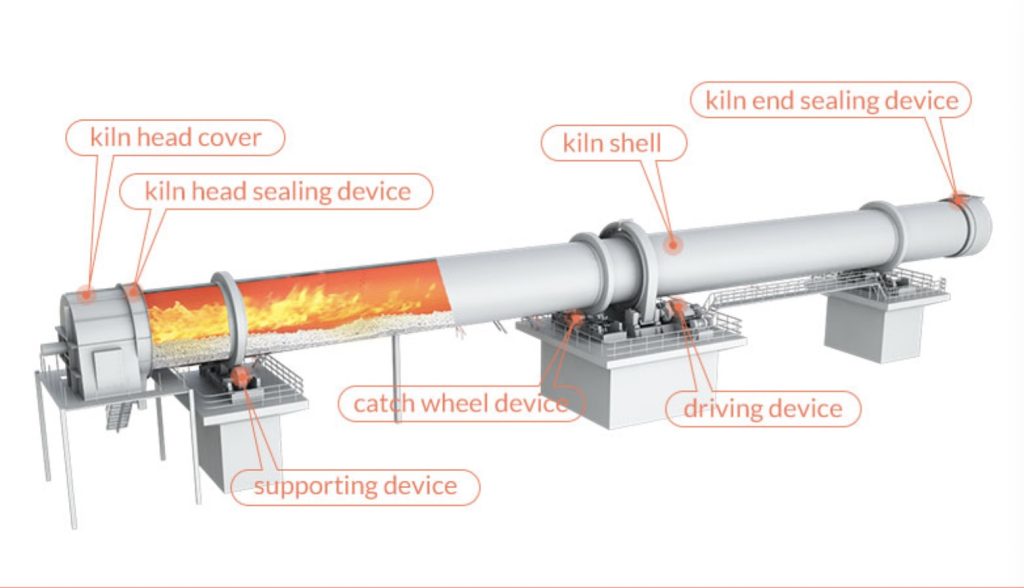

Rotary kiln is a cylindrical container with a slight inclination to the horizontal plane, the material is fed into the kiln shell by the kiln head for calcination, the fuel is injected from the kiln tail for combustion, and the hot air is blown into the kiln from the kiln tail, which impacts the raw material directly, and due to the inclination of the kiln shell and the low-speed rotation, the raw material is tilted along the axial direction from the high end to the low end of the circumferential direction of flopping, mixing, and the material is calcined into the maturity through the decomposition, calcining, and cooling, and is discharged from the low end.

| Product Specification (m) | Kiln dimensions | Motor power (kw) | ||||

| Diameter (m) | Length (m) | Obliquity (%) | Capacity (t/d) | Rotation speed (r/min) | ||

| Φ2.5×40 | 2.5 | 40 | 3.5 | 180 | 0.44-2.44 | 55 |

| Φ2.5×50 | 2.5 | 50 | 3 | 200 | 0.62-1.86 | 55 |

| Φ2.5×54 | 2.5 | 54 | 3.5 | 280 | 0.48-1.45 | 55 |

| Φ2.7×42 | 2.7 | 42 | 3.5 | 320 | 0.10-1.52 | 55 |

| Φ2.8×44 | 2.8 | 44 | 3.5 | 450 | 0.437-2.18 | 55 |

| Φ3.0×45 | 3 | 45 | 3.5 | 500 | 0.5-2.47 | 75 |

| Φ3.0×48 | 3 | 48 | 3.5 | 700 | 0.6-3.48 | 100 |

| Φ3.0×60 | 3 | 60 | 3.5 | 800 | 0.3-2 | 100 |

| Φ3.2×50 | 3.5 | 50 | 4 | 1000 | 0.6-3 | 125 |

| Φ3.3×52 | 3.3 | 52 | 3.5 | 1300 | 0.266-2.66 | 125 |

| Φ3.5×54 | 3.5 | 54 | 3.5 | 1500 | 0.55-3.4 | 220 |

| Φ3.6×70 | 3.6 | 70 | 3.5 | 1800 | 0.25-1.25 | 125 |

| Φ4.0×56 | 4 | 56 | 4 | 2300 | 0.41-4.07 | 315 |

| Φ4.0×60 | 4 | 60 | 3.5 | 2500 | 0.396-3.96 | 315 |

| Φ4.2×60 | 4.2 | 60 | 4 | 2750 | 0.41-4.07 | 375 |

| Φ4.3×60 | 4.3 | 60 | 3.5 | 3200 | 0.396-3.96 | 375 |

| Φ4.5×66 | 4.5 | 66 | 3.5 | 4000 | 0.41-4.1 | 560 |

| Φ4.7×74 | 4.7 | 74 | 4 | 4500 | 0.35-4 | 630 |

| Φ4.8×74 | 4.8 | 74 | 4 | 5000 | 0.396-3.96 | 630 |

| Φ5.0×74 | 5 | 74 | 4 | 6000 | 0.35-4 | 710 |

| Φ5.6×87 | 5.6 | 87 | 4 | 8000 | Max4.23 | 800 |

| Φ6.0×95 | 6 | 95 | 4 | 10000 | Max5 | 950×2 |

We are a professional machinery manufacturer that produces and sells our own products.

You can bring materials to the factory to test the machine

We will customize the solution according to your needs

60S Quick response

Minutes Technical reply

Hours design proposal

whatsApp

whatsApp