Single Cylinder Cone Crusher is mainly used in the second-stage intermediate crushing and third-stage.

Application areas:

suitable for crushing and screening operations of various sand and gravel aggregates, mine crushing, building stone crushing operations, etc.

Application materials:

medium and fine crushing of hard rocks such as iron ore, gold ore, non-ferrous metal ore, granite, quartzite, basalt, etc.

Single Cylinder Cone Crusher is mainly used in the second-stage intermediate crushing and third-stage fine crushing in metal mines and sand and gravel aggregate processing. Crusher safety, adjustment, and locking all use hydraulic devices, so it has what other crushers do not have. It is convenient to adjust the discharge port, and the overload coefficient is small when passing non-crushed objects. It is easy to take out the non-crushed objects that are blocked in the crushing cavity.

Zhongya Single Cylinder Cone Crusher is mainly used in the second-stage intermediate crushing and third-stage fine crushing in metal mines and sand and gravel aggregate processing. Crusher safety, adjustment, and locking all use hydraulic devices, so it has what other crushers do not have. It is convenient to adjust the discharge port, and the overload coefficient is small when passing non-crushed objects.With full automatic control system, this machine can realize accurate regulation

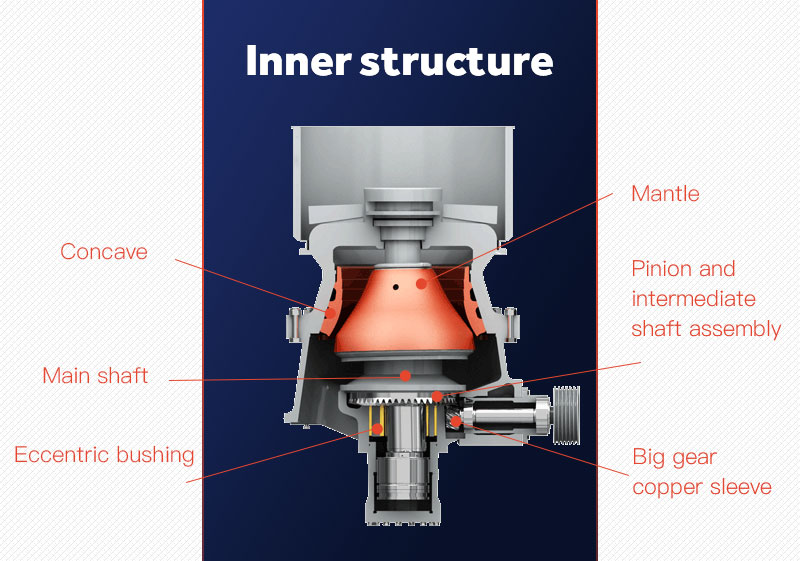

The electromotor leads the eccentric sleeve to rotate by the V-belt, drive shaft and drive gear. The movable cone does rotary and pendulum movement under the leading role of eccentric sleeve which makes the movable cone and fixed cone close and far away from time to time. The raw material is crushed in the crusher chamber by squeezing and striking continuously. The crushed stone discharges from the bottom.

| Model | Cavity | Open side feeding size (mm) | Closed side feeding size (mm) | Min outlet size (mm) | Capacity (t/h) | Power (kw) |

| HPG100 | C1(Extra Coarse) | 175 | 140 | 19 | 45-100 | 90 |

| C2(Coarse) | 125 | 105 | 13 | |||

| M(Middle) | 100 | 70 | 10 | |||

| F1(Fine) | 71 | 50 | 9 | |||

| F2(Extra Fine) | 33 | 20 | 6 | |||

| HPG200 | C2(Coarse) | 235 | 190 | 19 | 65-250 | 160 |

| M(Middle) | 171 | 120 | 16 | |||

| F1(Fine) | 150 | 95 | 13 | |||

| F2(Extra Fine) | 116 | 70 | 8 | |||

| HPG300 | C1(Extra Coarse) | 265 | 230 | 25 | 85-440 | 220 |

| C2(Coarse) | 240 | 210 | 20 | |||

| M(Middle) | 190 | 150 | 15 | |||

| F1(Fine) | 145 | 105 | 11 | |||

| F2(Extra Fine) | 120 | 80 | 8 | |||

| HPG400 | C1(Extra Coarse ) | 360 | 290 | 30 | 135-625 | 315 |

| C2(Coarse) | 310 | 250 | 25 | |||

| M(Middle) | 260 | 196 | 20 | |||

| F1(Fine) | 182 | 110 | 13 | |||

| F2(Extra Fine) | 135 | 90 | 10 | |||

| HPG500 | C1(Extra Coarse) | 370 | 330 | 38 | 200-790 | 400 |

| C2(Coarse) | 320 | 290 | 28 | |||

| M(Middle) | 245 | 210 | 22 | |||

| F1(Fine) | 180 | 130 | 13 | |||

| F2(Extra Fine) | 150 | 95 | 10 | |||

| HPG800 | C1(Extra Coarse) | 450 | 352 | 38 | 265-1200 | 630 |

| C2(Coarse) | 373 | 298 | 32 | |||

| M(Middle) | 340 | 275 | 25 | |||

| F1(Fine) | 280 | 230 | 16 | |||

| F2(Coarse Fine) | 235 | 150 | 10 |

We are a professional machinery manufacturer that produces and sells our own products.

You can bring materials to the factory to test the machine

We will customize the solution according to your needs

60S Quick response

Minutes Technical reply

Hours design proposal

whatsApp

whatsApp