Spiral classifiers are widely used in ore dressing plants and ball mills to classify ore in closed-circuit cycles to obtain ore particles of a certain fineness and improve grinding efficiency.

Application:

limestone, talc, graphite, barite, mica, etc.

Spiral classifier plays a very important role in the grinding operation. In the mineral processing operation, the spiral classifier works with the ball mill to form a closed-loop circulation process. The minerals that meet the particle size requirements discharge from the flow channel end to the lower process flow as finished products, while the coarse sand returns to the ball mill for re-grinding. Mineral processing plants widely use spiral classifiers.

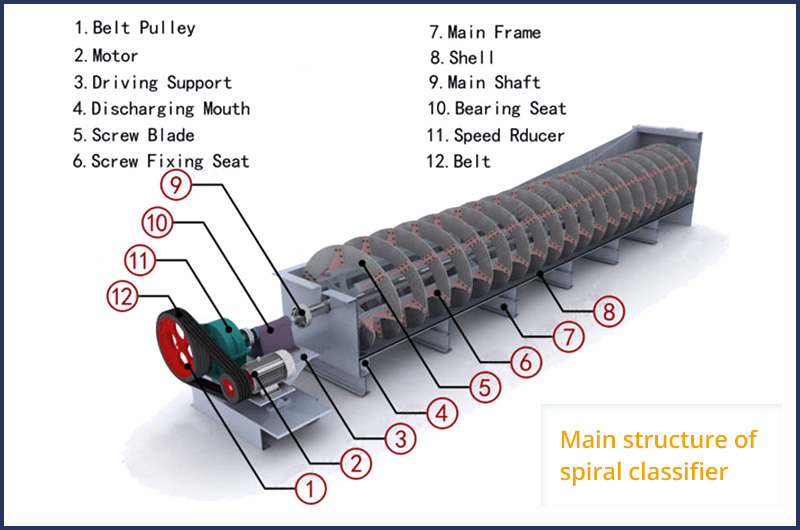

The spiral classifier is based on the different sizes and specific gravities of solid particles, and thus has different falling speeds. Fine ore particles float on the water surface and overflow. Coarse ore particles sink to the bottom of the trough, and the spiral pushes them up. It can filter the material in the machine and then rotate the coarse particles to the feeding part through the spiral blades. The fine particles are discharged from the overflow pipe for mechanical classification.

| Model | Spiral diameter(mm) | Speed of Spiral(r/min) | Power (kw) | Slope (°) | Power(KW) | |

| Sand Return (t/h) | Overflow (t/h) | |||||

| FG500 | 500 | 8-12.5 | 6-11 | 32 | 12-18 | 1.1 |

| FG750 | 750 | 6-10 | 11-24 | 65 | 12-18 | 3 |

| FG1000 | 1000 | 5-8 | 25-45 | 110 | 12-18 | 5.5 |

| FG1200 | 1200 | 4-6 | 50-80 | 155 | 12-18 | 7.5 |

| FG1500 | 1500 | 4-6 | 70-115 | 235 | 12-18 | 7.5 |

| FG1800 | 1800 | 2.5-6 | 100-190 | 310 | 12-18 | 11 |

| FG2000 | 2000 | 3.6-5.5 | 160-230 | 400 | 12-18 | 15 |

We are a professional machinery manufacturer that produces and sells our own products.

You can bring materials to the factory to test the machine

We will customize the solution according to your needs

60S Quick response

Minutes Technical reply

Hours design proposal

whatsApp

whatsApp