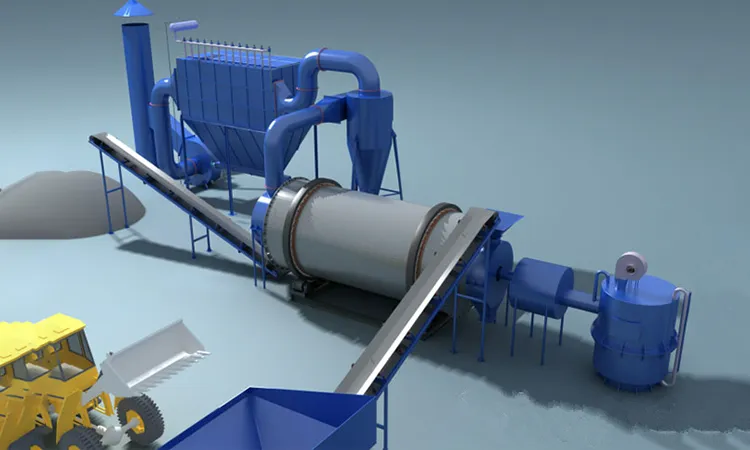

Sand dryer is a drying equipment used to dry all kinds of sand containing a certain amount of moisture

Applicable materials:

River sand, dry mortar, yellow sand, cement factory slag, clay, coal gangue, mixed materials, fly ash, straw powder, wood chaff, etc.

Three cylinder dryer is also known as three return cylinder dryer. Three cylinder sand dryer is to change the single cylinder dryer into three nested cylinders, shorten the overall size of the dryer body and improve the drying efficiency.

Sand is a common granular materials, due to special needs, need to be dried to normal use. The current sand dryer drying materials are mostly used in dry mortar, sand casting, dry beneficiation and other fields. The three-cylinder sand dryer is widely used for drying various materials including sand, slag, clay, coal, iron powder, and mineral powder across multiple industries. It is particularly suitable for processing dry mortar, river sand, and yellow sand in the construction industry.

Materials from the feeding device into the inner drum, to achieve the downstream drying process, and then from the other end into the inner wall of the middle layer, to achieve the countercurrent drying process, the material in the middle layer of both fully absorbing the heat emitted by the inner layer of the drum, but also absorbed the middle layer of the drum's heat, and at the same time to extend the drying time, the material in this dry state.

The material travels to the other end of the middle layer and falls into the outer layer. The material in the outer layer of the drum is a rectangular multi-circuit way of travelling, to achieve the drying effect of the material under the action of the hot air quickly travelling out of the drum, not to achieve the drying effect of the wet material due to the weight of the material can not quickly travel, the material in this rectangular coping for full drying, thus completing the purpose of drying.

| Model | Diameter of outer cylinder(m) | Length of outer cylinder (m) | Drum volume(m³) | Rotation speed(r/min) | Max. air flow temperature(℃) | Production capacity(t/h) | Power(kw) |

| Ф2.0*4m | 2 | 4 | 12.56 | 4-10 | 700-750 | 8-15 | 5.5x2 |

| Ф2.2*5m | 2.2 | 5 | 18.99 | 4-10 | 700-750 | 12-20 | 5.5x2 |

| Ф2.5*6m | 2.5 | 6 | 29.43 | 4-10 | 700-750 | 18-28 | 7.5x2 |

| Ф2.8*6m | 2.8 | 6 | 36.92 | 4-10 | 700-750 | 25-35 | 11x2 |

| Ф3.0*6m | 3 | 6 | 42.39 | 4-10 | 700-750 | 30-40 | 7.5x4 |

| Ф3.0*7m | 3 | 7 | 49.45 | 4-10 | 700-750 | 30-45 | 7.5x4 |

| Ф3.2*7m | 3.2 | 7 | 56.27 | 4-10 | 700-750 | 35-55 | 11x4 |

| Ф3.6*8m | 3.6 | 8 | 81.39 | 4-10 | 700-750 | 55-75 | 18.5x4 |

We are a professional machinery manufacturer that produces and sells our own products.

You can bring materials to the factory to test the machine

We will customize the solution according to your needs

60S Quick response

Minutes Technical reply

Hours design proposal

whatsApp

whatsApp