Drum screen is a very widely used machinery in the sorting technology, it is through the particle size of the particles to control the waste sorting, sorting high precision

During operation, the vibrating feeder can evenly, regularly and continuously deliver block and granular objects from the storage bin to the receiving device. In the sand and gravel production line, it can continuously and evenly feed the crushing machinery and perform coarse screening of the materials. It is widely used in crushing and screening operations in metallurgy, coal mining, mineral processing, building materials, chemical industry, abrasive and other industries.

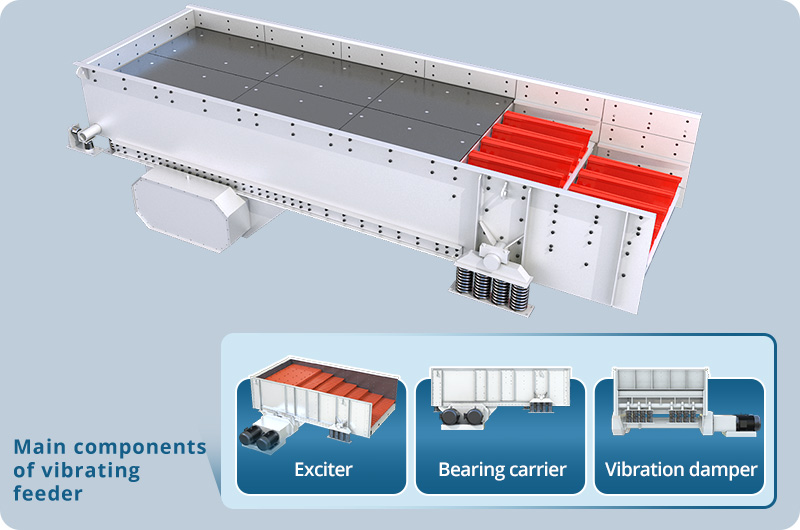

Vibrating feeder is composed of feeding trough body, vibrator, spring support, transmission device and so on. The vibrator is composed of two eccentric shafts (active and passive) and gears, the motor drives the active shaft through the triangle belt, the material slides and moves forward on the screen mesh, when the material passes through the screening section, the smaller material falls down to avoid further crushing, so as to achieve the purpose of screening.

| Model | Tank Dimensions (mm) | Max. Feed Size (mm) | Feed Capacity (t/h) | Rotating Speed of Eccentric Shaft (r/min) | Motor Power (kW) | Weight (kg) |

| ZSW380X95 | 3800X950 | 500 | 96~160 | 800 | 11 | 4082 |

| ZSW420X110 | 4200X1100 | 500 | 110~180 | 800 | 15 | 4149 |

| ZSW490X110 | 4900X1100 | 500 | 115~192 | 800 | 15 | 4263 |

| ZSW590X110 | 5900X1100 | 630 | 350~500 | 800 | 22 | 6130 |

| ZSW600X130 | 6000X1300 | 750 | 400~560 | 800 | 22 | 7800 |

We are a professional machinery manufacturer that produces and sells our own products.

You can bring materials to the factory to test the machine

We will customize the solution according to your needs

60S Quick response

Minutes Technical reply

Hours design proposal

whatsApp

whatsApp