VSI high-efficiency vertical shaft impact crusher is a sand making machine that can provide the best sand and gravel raw materials for highways, railways, construction projects, concrete mixing plants, etc.

Application fields:

metal and non-metallic ore, building materials, artificial sand and various metallurgical slag crushing and shaping.

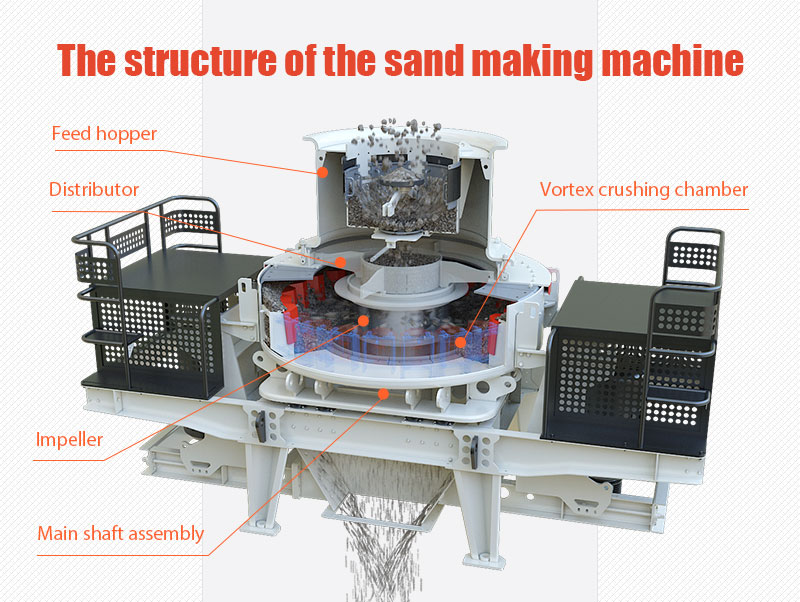

Vertical shaft impact crusher, also known as VSI sand making machine, has high-efficiency performance, and its performance plays an irreplaceable role in various ore fine crushing equipment. It consists of seven parts: feeder, distributor, vortex crushing chamber, impeller experience, main shaft assembly, base transmission device and motor. VSI sand making machine is mainly used to produce construction sand. It is the most advanced artificial sand production equipment at present. VSI sand making machine aims to provide high-quality sand and gravel aggregates for highways, high-speed railways, buildings, hydropower dam construction, and concrete mixing plants. This machine also serves in artificial sand production and stone shaping applications. VSI sand making plants typically combine sand washers, stone crushers, and vibrating screens to produce artificial sand more economically and efficiently.

The material falls directly from the upper part of the machine onto the high-speed rotating turntable. High-speed centrifugal force propels the material outward, where it violently collides with umbrella-distributed target stones surrounding the turntable, achieving high-density crushing. Colliding stones create violent eddy currents between the turntable and casing. These turbulent forces drive multiple mutual impacts, generating intense friction that crushes the material. The processed aggregates then discharge directly through the bottom outlet. This forms a closed-loop multiple cycle, and the screening equipment controls the required particle size.

| Model | VSI-7611 | VSI-8518 | VSI-9526 | VSI-1140 | VSI-1145 | |

| Capacity (t/h) | Cascade and Center Feeding | 120-180 | 200-260 | 300-360 | 450-520 | 490-600 |

| Center Feeding | 60-90 | 100-130 | 150-190 | 225-260 | 250-310 | |

| Feeding Size (mm) | Soft Material | < 35 | < 40 | < 45 | < 50 | < 50 |

| Hard Material | < 30 | < 35 | < 40 | < 45 | < 45 | |

| Rotation Speed (r/min) | 1700-1890 | 1520-1690 | 1360-1510 | 1180-1310 | 1180-1280 | |

| Power of the Double Motors (kw) | 110-150 | 180-220 | 264-320 | 400-440 | 440-520 | |

| Overall dimension L*W*H (mm) | 3700*2150*2100 | 4140*2280*2425 | 4560*2447*2278 | 5000*2700*3300 | 5100*2790*3320 | |

| Power Source | 380v:50hz | |||||

| Vibrating Sensor | Inspection Scope:0.1-20mm/s, it can be adjusted continuously. | |||||

| Hydraulic Lubrication Station | Power of Double Oil Pump | 2x0.31kw | ||||

| Safety | Double oil pumps make sure supply of oil with; Stop automatically without oil flow or oil pressure; Water cooled; Heating start the motor in winter. | |||||

| Overall Dimension L*W*H (mm) | 820x520x1270 | |||||

| Power of Oil-Box Heater | 2kw | |||||

We are a professional machinery manufacturer that produces and sells our own products.

You can bring materials to the factory to test the machine

We will customize the solution according to your needs

60S Quick response

Minutes Technical reply

Hours design proposal

whatsApp

whatsApp