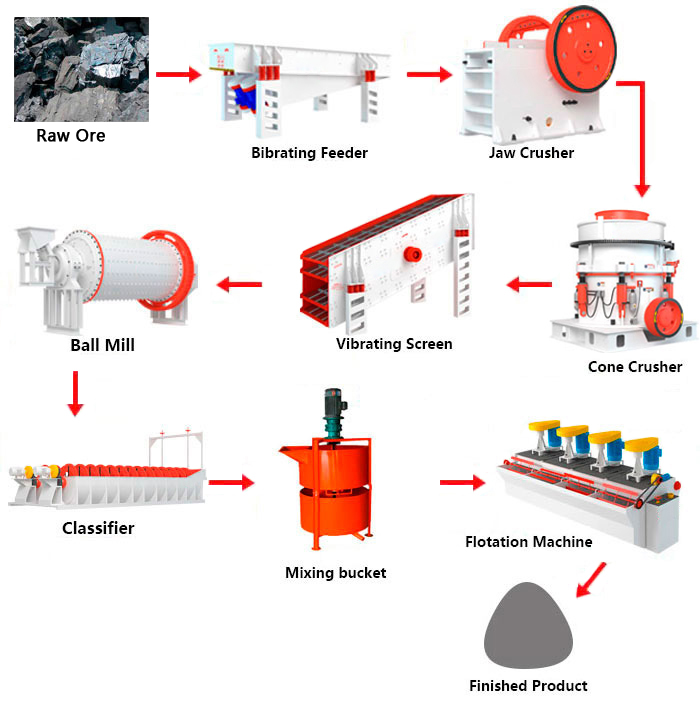

The basic process of copper ore beneficiation is crushing, grinding, screening, flotation separation and dewatering. The specific process varies according to the ore, site and customer requirements. Copper ore flotation processing plant is mainly composed of jaw crusher, ball mill, spiral classifier, mixer, flotation machine.

Industries such as aerospace, machinery manufacturing, and electronic power widely use copper as a key metal raw material due to its good electrical conductivity, thermal conductivity, ductility, and corrosion resistance. The cooper ore processing line mainly relies on specialized equipment to refine the ore. This process will eventually yield pure copper with greatly increased value. The specific flow process will provide EPC solutions according to the site and customer.

1:Crushing

The loader feeds the raw ore into the vibrating feeder. The vibrating feeder conveys the material evenly into the jaw crusher for the preliminary crushing process. The beneficiation process may incorporate a cone crusher or hammer crusher for secondary crushing when necessary to achieve optimally sized particles.

Required equipment; vibrating feeder, jaw crusher, cone crusher or hammer crusher

2:Grinding

The crushed material passes through the vibrating screen into the ball mill, through the mill for fine treatment

Required equipment: ball mill, spiral classifier

3:Separation

Copper ore flotation: the slurry is fed into the flotation machine. Add the chemicals and mix thoroughly to select the useful ore powder. Aerated by stirring, so that the mineral particles selectively fixed in the air bubbles on top. Floating to the surface of the slurry is scraped out to form a foam product. The rest of the slurry is retained in the slurry, in order to achieve the purpose of separating the minerals

Required equipment: flotation machine, shaking table

4: Drying

The obtained copper powder is fed into the desiccant for drying to get the required material.

The selection and combination of these equipments depends on the nature of copper ore, beneficiation process and production scale and other factors. Engineers typically select and configure equipment based on specific conditions in practical applications to achieve optimal beneficiation results and economic benefits.

We are a professional machinery manufacturer that produces and sells our own products.

You can bring materials to the factory to test the machine

We will customize the solution according to your needs

60S Quick response

Minutes Technical reply

Hours design proposal

whatsApp

whatsApp