At present, the common iron ores are magnetite, hematite, limonite, according to the magnetic strength of the ore to choose different iron ore beneficiation process, magnetic separation process is the main method of iron ore beneficiation.

Iron ore beneficiation is the process of obtaining high grade iron ore concentrate by separating useful iron ore minerals from unwanted vein minerals and enriching iron ore minerals through a series of physical, chemical and physicochemical methods from ores containing iron ore. The specific process technology Zhongya Machinary will provide EPC solutions according to the site and customer's situation.

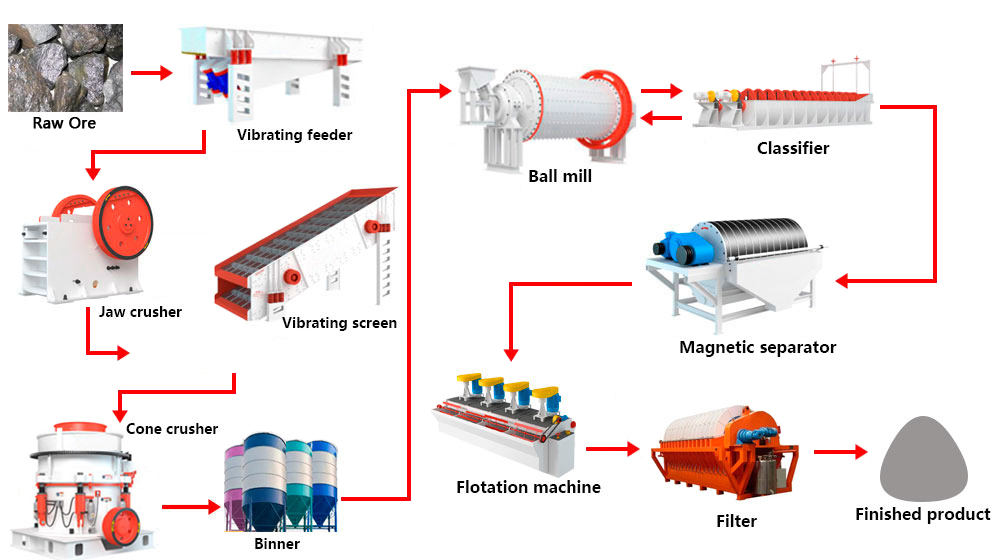

1:Crushing

Used to crush large iron ore into smaller particles

Required equipment: hopper, vibrating feeder, jaw crusher, cone crusher

2:Grinding

The crushed iron ore is further ground to reach the required particle size for mineral processing.

Required equipment: ball mill, spiral classifier

3:Magnetic Separation

According to the magnetic difference of the iron ore for sorting, commonly used permanent magnetic cylinder magnetic separator, wet magnetic separator

Required equipment: strong magnetic separator, weak magnetic separator, high efficiency sieve, etc.

4: Tailings treatment

After obtaining magnetite concentrate, the beneficiation plant uses tailings treatment equipment to process the produced tailings. The plant then concentrates, dewaters, and dries these tailings.

The selection and combination of these equipments depends on the nature of iron ore, beneficiation process and production scale and other factors.In actual operations, mineral processing plants select and configure equipment based on ore characteristics to optimize both recovery rates and economic returns.

We are a professional machinery manufacturer that produces and sells our own products.

You can bring materials to the factory to test the machine

We will customize the solution according to your needs

60S Quick response

Minutes Technical reply

Hours design proposal

whatsApp

whatsApp