Stones crushing plant usually consists of primary, secondary and tertiary crushers, screens, conveyors and other equipment required for the crushing process. It can produce gravel of various grain sizes, including limestone, granite, dolomite, quartz, ballast, basalt, marble, iron ore, copper ore, and so on.

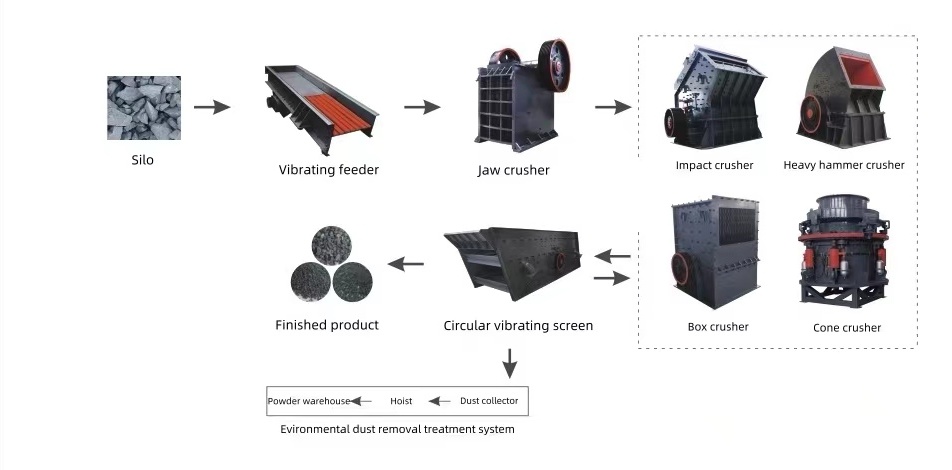

Stone crushing line crushing equipment generally consists of jaw crusher, impact crusher, cone crusher, hammer crusher, mobile crushing plant and so on. In addition, it also needs silo, vibrating screen, sand washer and other equipment required for the crushing process to be composed. Stone crusher production line is widely used in mining, metallurgy, building materials, highway, railway, water conservancy, chemical industry, etc. It has the advantages of large crushing ratio, even particle size, simple structure, convenient maintenance and economic operation.

Usually, jaw crusher is suitable for primary crushing, and the commonly used models for secondary crushing process are impact crusher, cone crusher, hammer crusher, and according to the requirements of the finished product, it can be used with sand making machine for shaping.

1.Selection of crushing programme

Hard materials: granite, basalt, river pebbles, cobbles, etc.

Equipment selection: jaw crusher + cone crusher

More specifications, large-scale production, wide range of application, easy to adjust the ratio of product varieties, good product shape, less powder, and strong adaptability to medium and high hardness index materials.

According to the requirements of the finished product with the use of impact crusher for shaping, in order to eliminate the stone in the crushing process produced by the needle flake and internal cracks, and finally the use of vibrating screen for sorting.

2.Selection of crushing programme

Hardness material: limestone, weathered stone, soft rock, etc.

Equipment selection: jaw crusher + impact crusher

More specifications, large-scale production, wide range of application, easy to adjust the ratio of product varieties, less powder, strong adaptability to medium and soft hardness index materials.

3.Selection of crushing programme

Hard selection: limestone, coal gangue

Equipment selection: hammer crusher

Hammer crusher is the equipment to form the material once, it has the characteristics of simple structure, large crushing ratio and high production efficiency.

whatsApp

whatsApp